Programa de reducción de riesgo y energía

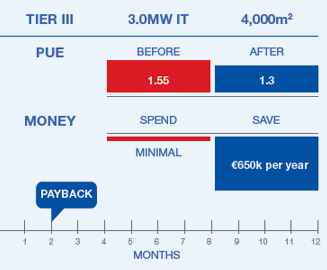

Brief

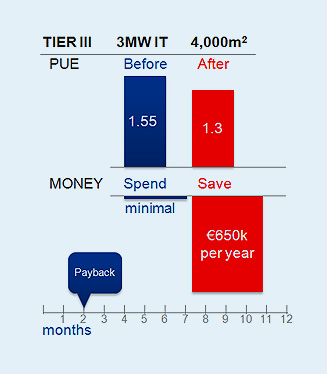

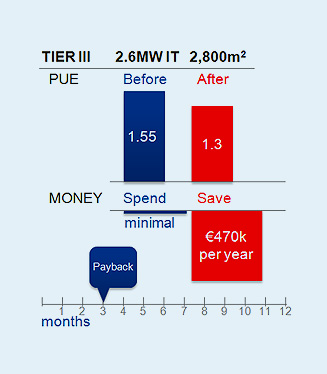

Two award winning Tier III facilities wanted to make further improvements to their energy performance.

Recommended changes

Air Management

- Seal air gaps to reduce bypass (data halls), reduce flow rate (LV switchrooms), relocate poorly placed grilles (MDF), redirect air to IT intake (MDF)

Energy

- Run all AHUs at a lower fan speed (data halls)

- Reduce pressure set points (data halls)

- Replace pressure sensors with ones with a tighter range (data halls)

- Reduce flow rates in LV switchrooms

- Allow higher temperature in LV switchrooms (no batteries)

- Reduce pressure set points (MDF)

Risk

- Review and improve standard and emergency procedures

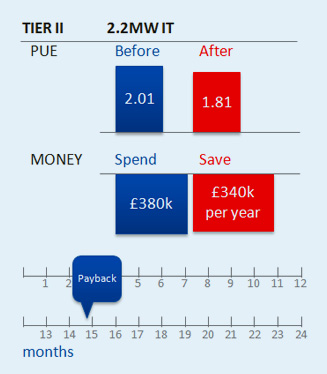

Brief

London facility that had already targeted energy reduction.

Recommended changes

Phase 1

- Further air management – improved grille placement, blanking plates, and sealing of gaps in cabinets and floors

- Increased CRAC set points and free cooling

- Retrofitting of VFDs (to enable reduced fan speeds).

- Reduced fresh air volume of AHU (previously over-supplied)

- Lighting controls (previously lights were permanently on)

Phase 2

- Semi-containment (25% of the facility)

- Further increase of CRAC set points

- Reconfiguring of CRAC fan speeds in UPS room and data halls

Phase 3

- Semi-containment (remaining spaces)

- Further increase of set points

- Study of supply control and subsequent upgrade of control cards

- Removal of unrequired under floor cabling

- Solar gain window film

- Study of pump controls

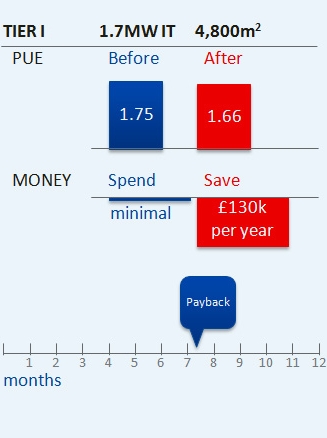

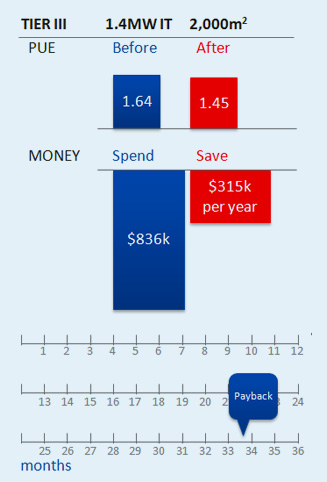

Brief

London facility. Some energy saving best practices had already been targeted.

Recommended changes

- New UPSs to replace single unit

- CRAC unit upgrades

- Ultrasonic humidification (very low energy)

- Implementation of 4 No. glycol pumps with VSDs, and lowering of fan speeds

- New PMS (power monitoring system) Front End

- Replace DAC (dry air cooler) fans with EC direct drive units

- Replacement of 3 No. chillers because of R22 gas use

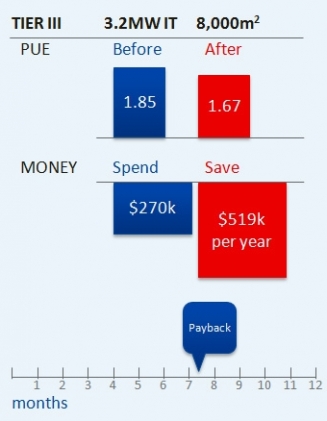

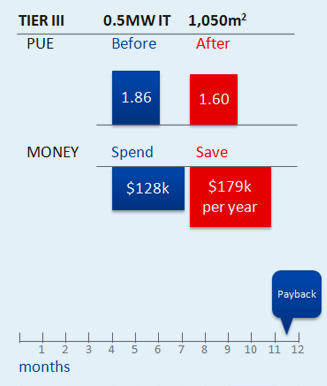

Brief

Target energy savings whilst managing risk at Swindon facility.

Recommended changes

- Install blanking plates

- Curtains (for containment) and return grilles to network rows

- Reduce pressure set points

- Seal gaps in aisles where cabinets are missing

- Relocate poorly placed floor grilles

- Cold aisle containment

- Review scoop direction

- Change cabinet doors to increase open area/airflow

- Angled grilles

- Improve processes for Colo installations

Brief

Target energy savings whilst managing risk at Santiago campus hosting facility with cooling towers.

Recommended changes

Improve air management throughout the facility

- Take temperature readings for IT and cooling equipment

- Establish levels of bypass, recirculation, negative pressure and air availability

- Install air management best practices – blanking plates, grille replacement to improve air flow, rotate backward facing equipment, cold aisle containment and sealing of cable holes.

Improve PUE

- VFD fan installation

- Optimise humidity control

- Descaling of cooling plant

- Lighting automation

- Change set points of generator heaters

Improve teamwork – better communication between teams and improved excellence, quality and compliance.

Brief

Target energy savings whilst managing risk at campus of legacy hosting facility in Chile with chilled water & DX cooling.

Recommended changes

- Improve/implement free cooling

- Descaling of cooling plant

- Improve air management

- VFD fans and reduced fan speeds (once air management has been improved)

Brief

Help low energy design reach full potential at direct air free cooling facility in Dublin.

Recommended changes

Air management

- Measure and monitor air performance metrics

- Seal air gaps to reduce bypass air in data hall

- Revise rack and hardware deployment and decommissioning processes to include air management

Energy

- Optimisation of control strategy

- Reduce fan speeds in line with flow availability requirements

- Analysis of data hall pressure profile

- Replace pressure sensors with ones with a tighter range

Risk

- Review and improve standard and emergency procedures

Explotando el free cooling en el Reino Unido

Explotando el free cooling en el Reino Unido