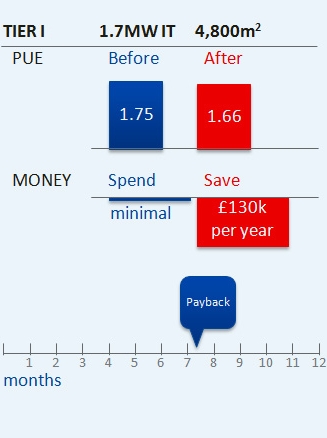

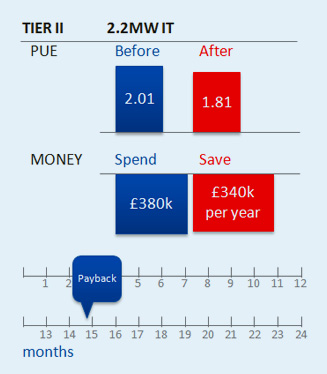

London facility that had already targeted energy reduction

Recommended changes:

Phase 1

- Further air management – improved grille placement, blanking plates, and sealing of gaps in cabinets and floors

- Increased CRAC set points and free cooling

- Retrofitting of VFDs (to enable reduced fan speeds).

- Reduced fresh air volume of AHU (previously over-supplied)

- Lighting controls (previously lights were permanently on)

Phase 2

- Semi-containment (25% of the facility)

- Further increase of CRAC set points

- Reconfiguring of CRAC fan speeds in UPS room and data halls

Phase 3

- Semi-containment (remaining spaces)

- Further increase of set points

- Study of supply control and subsequent upgrade of control cards

- Removal of unrequired under floor cabling

- Solar gain window film

- Study of pump controls

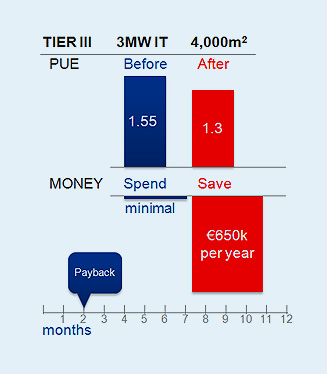

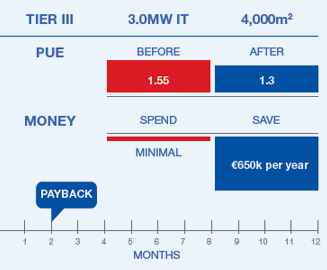

Two award winning Tier III facilities wanted to make further improvements to their energy performance

Recommended changes:

Air Management

- Seal air gaps to reduce bypass (data halls), reduce flow rate (LV switchrooms), relocate poorly placed grilles (MDF), redirect air to IT intake (MDF)

Energy

- Run all AHUs at a lower fan speed (data halls)

- Reduce pressure set points (data halls)

- Replace pressure sensors with ones with a tighter range (data halls)

- Reduce flow rates in LV switchrooms

- Allow higher temperature in LV switchrooms (no batteries)

- Reduce pressure set points (MDF)

Risk

- Review and improve standard and emergency procedures

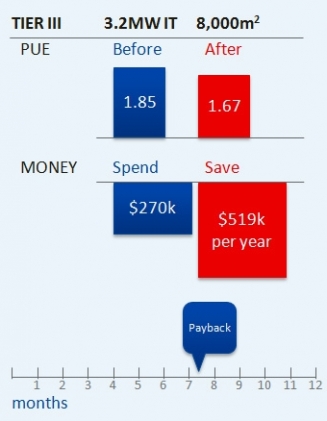

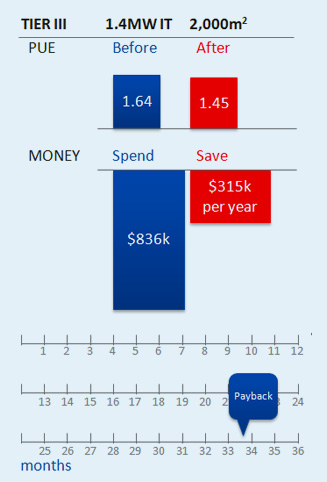

London facility. Some energy saving best practices had already been targeted

Recommended changes:

- New UPSs to replace single unit

- CRAC unit upgrades

- Ultrasonic humidification (very low energy)

- Implementation of 4 No. glycol pumps with VSDs, and lowering of fan speeds

- New PMS (power monitoring system) Front End

- Replace DAC (dry air cooler) fans with EC direct drive units

- Replacement of 3 No. chillers because of R22 gas use

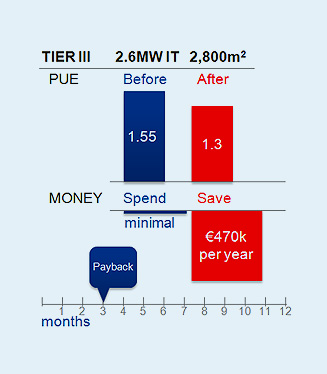

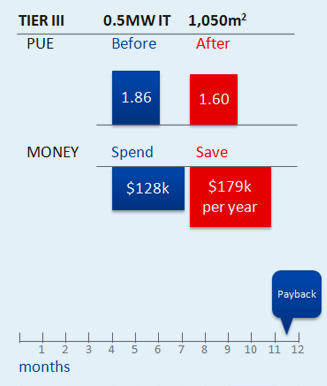

Target energy savings whilst managing risk at Swindon facility

Recommended changes:

- Install blanking plates

- Curtains (for containment) and return grilles to network rows

- Reduce pressure set points

- Seal gaps in aisles where cabinets are missing

- Relocate poorly placed floor grilles

- Cold aisle containment

- Review scoop direction

- Change cabinet doors to increase open area/airflow

- Angled grilles

- Improve processes for Colo installations

Target energy savings whilst managing risk at Santiago campus hosting facility with cooling towers

Recommended changes:

Improve air management throughout the facility:

- Take temperature readings for IT and cooling equipment

- Establish levels of bypass, recirculation, negative pressure and air availability

- Install air management best practices – blanking plates, grille replacement to improve air flow, rotate backward facing equipment, cold aisle containment and sealing of cable holes.

Improve PUE:

- VFD fan installation

- Optimise humidity control

- Descaling of cooling plant

- Lighting automation

- Change set points of generator heaters

Improve teamwork:

- Better communication between teams and improved excellence, quality and compliance.

Target energy savings whilst managing risk at campus of legacy hosting facility in Chile with chilled water & DX cooling

Recommended changes:

- Improve/implement free cooling

- Descaling of cooling plant

- Improve air management

- VFD fans and reduced fan speeds (once air management has been improved)

Help low energy design reach full potential at direct air free cooling facility in Dublin

Recommended changes:

Air management

- Measure and monitor air performance metrics

- Seal air gaps to reduce bypass air in data hall

- Revise rack and hardware deployment and decommissioning processes to include air management

Energy

- Optimisation of control strategy

- Reduce fan speeds in line with flow availability requirements

- Analysis of data hall pressure profile

- Replace pressure sensors with ones with a tighter range

Risk

- Review and improve standard and emergency procedures